conclusion for rockwell hardness test|background of rockwell hardness testing : store The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

WEBCada imagem da noiva é única e assustadora à sua maneira. Oferecemos-lhe uma seleção de imagens femininas para o Halloween no estilo “Noiva Cadáver”. Recomendamos nossa categoria de páginas para colorir para todos os temas de Halloween. Desenhos para colorir da Noiva Cadáver – 30 imagens

{plog:ftitle_list}

Resultado da Regardez la bande-annonce, trouvez des séances et réservez vos billets pour voir John Wick: Chapitre 4 sur le site officiel. En salle le 24 Mars 2023 présenté par Cineplex Pictures. Réalisé par: Chad Stahelski. Casting: Keanu Reeves, Donnie Yen, Bill Skarsgård, Laurence Fishburne, Hiroyuki .

The hardness test is a mechanical test for material properties which are used in engineering design, analysis of structures and material development. The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is . Conclusion The Rockwell Hardness number of the given specimen cast iron, brass, copper, aluminum were determined by this experiment. The specimen were differentiated according to their hardness scale obtained by . Enjoy the benefits of Rockwell hardness testing and the unprecedented accuracy it provides. In Conclusion. Despite its advantages, the Rockwell method is not exactly applicable at all instances. However, it does . Conclusion. To wrap, Rockwell hardness testing is very beneficial in many manufacturing processes that involve ascertaining the .

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

Conclusion. The Rockwell hardness test is widely used to standardize the hardness of metals. Although it is possible and easy to perform, it can be time-consuming and expensive. The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness test. Its main goal is understanding the concept of hardness and examining different properties .

Conclusion. Rockwell Hardness test is the most widely used method but in some cases Vickers Hardness testing method has to be used especially when thin parts have to be tested. It is important to look up the hardness scale standardized by ISO and ASTM while performing any hardness test to get accurate and reliable results. If you want to know .

The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the Rockwell C scale of hardness to determine the hardness of the material. . Conclusion. Rockwell hardness is a very important factor in manufacturing products. You need .Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go far outside from the specified depth of 0.2mm. . Conclusion. In this article, we have briefly .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

Rockwell hardness testing machine. . (IX) Conclusion: Based on BHN for Mild Steel, the Relation between the tensile strength . and Hardness Number is given as follows, In conclusion, the Rockwell hardness test is a widely used method for measuring the hardness of materials. It is a non-destructive and easy-to-perform test that provides fast and accurate results. The test has limitations, such as its suitability for certain materials and the effect of surface conditions on the accuracy of the results.In conclusion, getting the accurate hardness value for material using the Rockwell hardness value is highly dependent on understanding the working principle of this test method. Knowing its part, which includes the indenter types, the scales, and applicable loads, will help you identify its most suitable application.

Experiment 7: Rockwell Hardness Test - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. (1) The Rockwell hardness test is a common method to determine the hardness of metals and polymers using indentation. (2) An indenter applies a minor preload and then a major load, and the hardness number is based on the .Rockwell hardness test is one of the static hardness testing methods using indentation depth as a measuring criterion. Basically, two types of indenter are used; one Diamond spheroconical (Brale) indenter with an angle of 120 O and a spher ical tip of 0.2mm; second is steel ball indenter with diameters as 1/16, 1/8, 1/4, ½ inches. . • The obtained results for the Rockwell hardness test often deviate from the . Conclusions are drawn that the essential differences of the material removal mechanism between hard and brittle .In conclusion, the Rockwell hardness test serves as an indispensable tool for engineers, researchers, and manufacturers seeking to understand and characterize the mechanical properties of materials. Its simplicity, accuracy, and broad applicability make it a cornerstone in material testing and quality assurance across various

1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional examinations in the sequence. . Conclusion Although the Rockwell technique has benefits, it is only sometimes appropriate .Rockwell hardness test is used to calculate the hardness of a material. It can calculate the hardness of various materials such as aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This test provides you .Question: write a conclusion for the hardness test. write a conclusion for the hardness test . There are 2 steps to solve this one. Step 1. From this examination, we can reason that, ∙ Rockwell hardness of a steel example .

The Rockwell hardness test, developed by Stanley P. Rockwell, is known for its versatility and quick testing procedure. It offers various scales for different materials, making it suitable for a wide range of applications. .The Rockwell hardness test is cheaper and can be used on a wider range of materials, while the Vickers hardness test is expensive because of the optical measurement material used to take the measurements and the time required to perform the test. . Conclusion. The hardness test methods are fundamentally different in how they determine a .

The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .Hardness Testing Lab (Brinell and Rockwell) . 12 Conclusion This experiment was a complete success as accurate enough results were obtained although results were accurate .It can be seen from readings which are obtained in this experiment using two techniques rockwell and brinell hardness testing that the expected values and the obtained .Rockwell hardness testing is measured using the Rockwell hardness scale with the method defined in ASTM E18 and BS EN ISO 6508-1. . Conclusion. Brinell and Rockwell hardness tests are valuable methods for evaluating material hardness, each with its own advantages and considerations. While the Rockwell test offers simplicity and faster results . Conclusion. Some test methods are capable of testing hardness on a microscopic level, while others are designed to provide more of a “macroscopic” view. Each method has its own “scale” to help interpret the test results: examples include the Rockwell B and C scale or the HV10 scale for the Vickers hardness test.

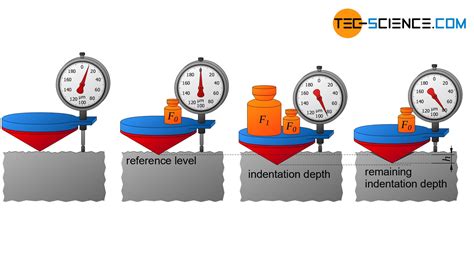

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .The amount of deformation that occurs when a small, hard steel ball or diamond point is pressed into a material surface at some designated load is the measure of the hardness of the material. Rockwell Hardness Test A Minor load Fo B Minor load Fo plus Major load F1 = Total load F с Minor load Fo Zero Reference line Figure 1: Rockwell .The Rockwell hardness test is more reliable and widely used. . Conclusion . As I mentioned above, knowing the hardness of the material is essential. It helps make the correct use of different materials to make products. However, different hardness testing machines are available. Their working, usage, and prominent features vary from each other.

1. Introduction. Rockwell hardness is an ordinal quantity measurement and is therefore dependent on a defined test method. In today’s international commerce, Rockwell hardness testing is almost exclusively conducted in compliance with the test methods specified by ASTM-International (test method ASTM E18) [] or the International Organization for Standardization .

купить влагомер зерна в краснодаре

7.2. EM ALTA 2023. O Sequestro do Voo 375. 8.3. EM ALTA 2023. Upgrade: As Cores do Amor. 7.1. EM ALTA 2024. A Noite que Mudou o Pop. 7.9. EM ALTA 2024. Orion e o .

conclusion for rockwell hardness test|background of rockwell hardness testing